Microbial control strategy can include helium and trace gas leak testing for sterile biotech, industrial fermentation

Fermentation Vessels Can Leak Through Any Seal or Fitting. Even Welds!

Even Shiny Clean Fermenters Can Leak

Scheduled Service During Downtime Finds Leaks

Bioproduction Contamination Can Occur With New Equipment

Pressure Decay and Visual Bubble Tests Are Useful, But May Not Find All of the Process Leaks

Microbial sterility control is challenging to achieve with today's biotech vessels. It can be nearly impossible with yesterday's vessels. After the first year, challenges managing biologic intrusions can begin to mount. There are several tests that technicians run to work to narrow down the sources.

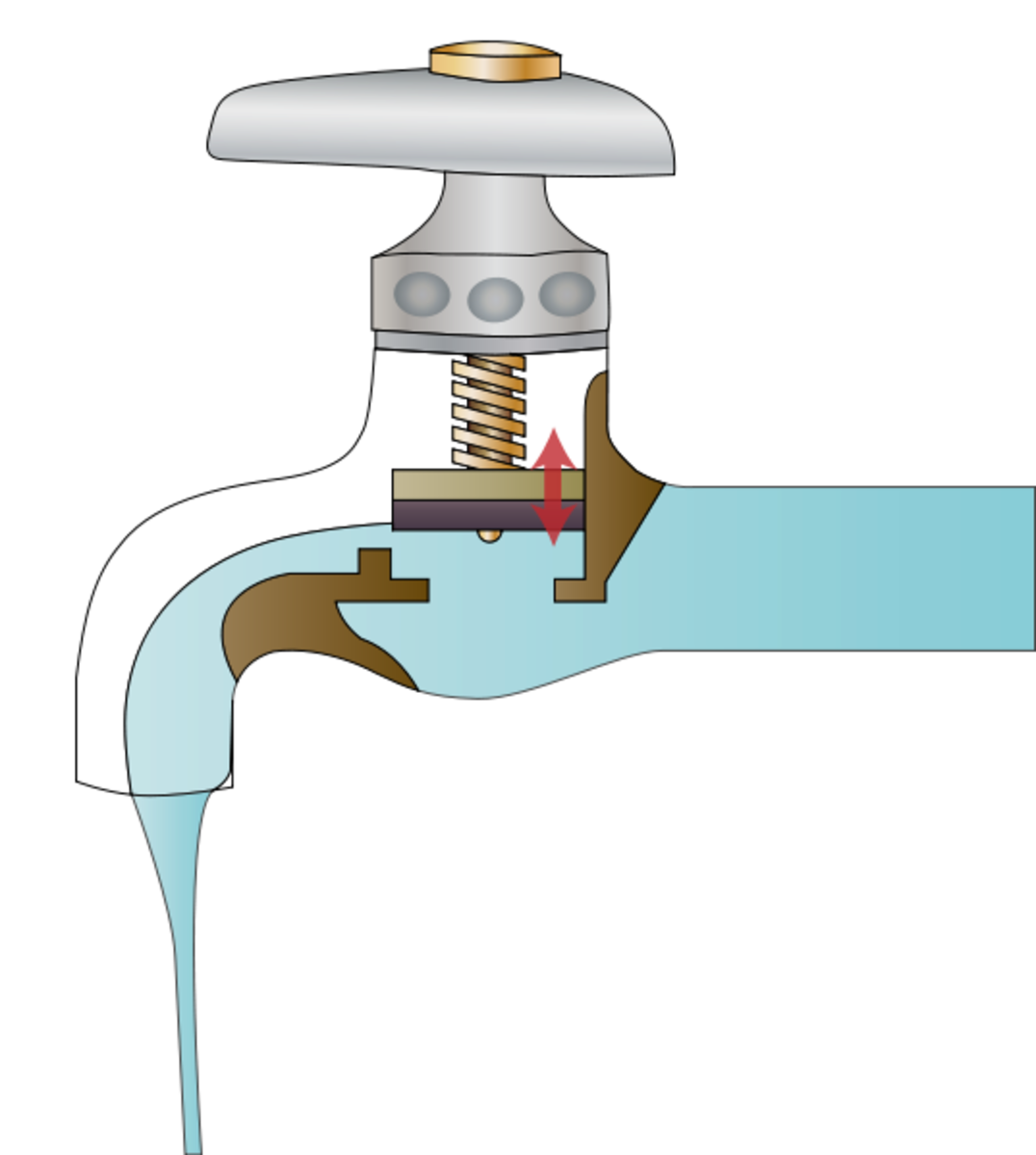

Pressure decay tests have been run not only on fermentation vessels, but on on kinds of closed systems for decades. It can work well to determine if a large leak is the cause of the system contamination. Generally, a vessel to be tested is isolated from the rest of the process, and is pressurized with clean, dry air to a few pounds of pressure. The amount of pressure added can vary depending on the purpose of the vessel and the normal operating pressure. Gauges are then used to monitor the pressure in the vessel and any pressure drop is assumed to be from the leak. Common leak locations can be check valves, and other valves that are not closing all of the way. Threaded fittings that have come loose can also account for a drop in pressure. This testing method frequently finds large leaks in the system. Smaller variations of the can be performed on isolated sections of piping and lines that may include several valves to/from the process. Limitations to this type of testing include temperature variations within the vessel and fluctuations during the testing, accuracy of the gauges being used to monitor the pressure, and the the fact that pressuring with air often allows for natural fluctuations due to the compressive nature of the air.

Visual testing can be done while the system is still under pressure from the pressure decay test. Once the pressure in the vessel is found to be dropping off, the search continues to find the exact cause of the pressure loss. Special bubble testing solutions can be used to pour, spray or brush over fittings, valves and any intrusion into the vessel the vessel that is being tested. Sometimes a bubble solution can be as simple as kitchen dish soap. Visual inspection is made to observe bubble that are formed where the dry air is bleeding off of the system. Once all of the found leak are repaired, the pressure decay test can be run again.

The limitations of the pressure decay test and the bubble test is that some processes require a level of tightness that cannot always be assured by these tests. Sometimes, trace gas detection can be performed on the vessels and can find leaks that are small enough to allow only a single bacterium into the process. If the process is PCR, fermentation, or even just for human consumption or pharmaceutical manufacturing, even a single bacterium can cause the whole contents of the process to be contaminated.

Fermentation processes are too valuable to rely on bubbling leak detection soap.

For a process this expensive, there must be a better solution than leak detection soap and hundreds of swabs. Solutions are available that can help to track down contamination sources. While trace gas detection is not the solution for every leak, it can help find current microbial contamination sources as well as the sources that are not yet large enough to allow adventitious agents into the process. It is part of a comprehensive microbial control strategy. Helium and inert hydrogen trace gas leak detection can help to find even the smallest leaks. Our equipment can test for leaks down to 1 x 10^-10 and in some cases, can even test for smaller leaks than that.

Run until it fails maintenance is not cost effective or efficient

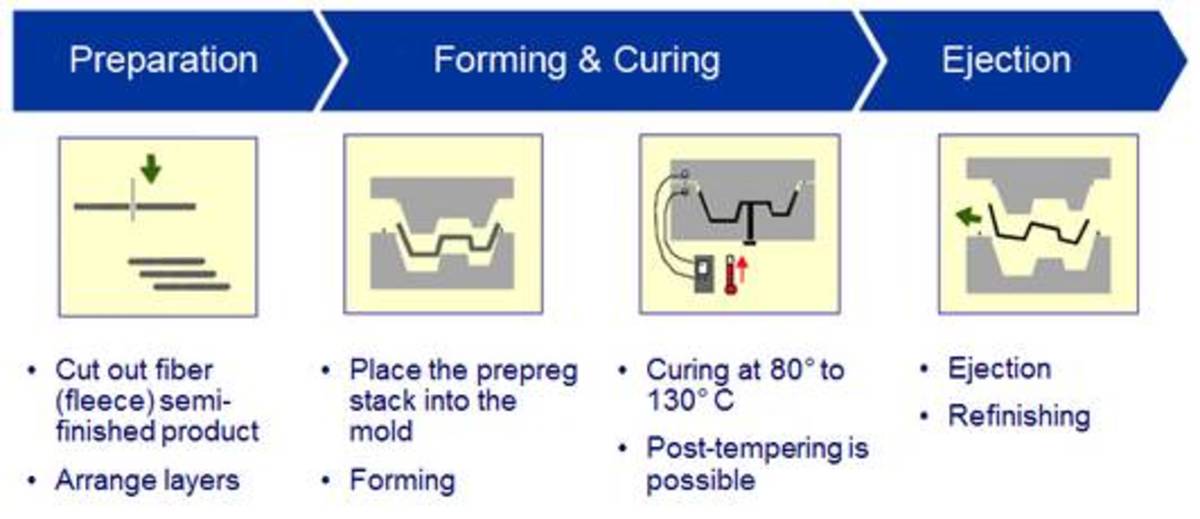

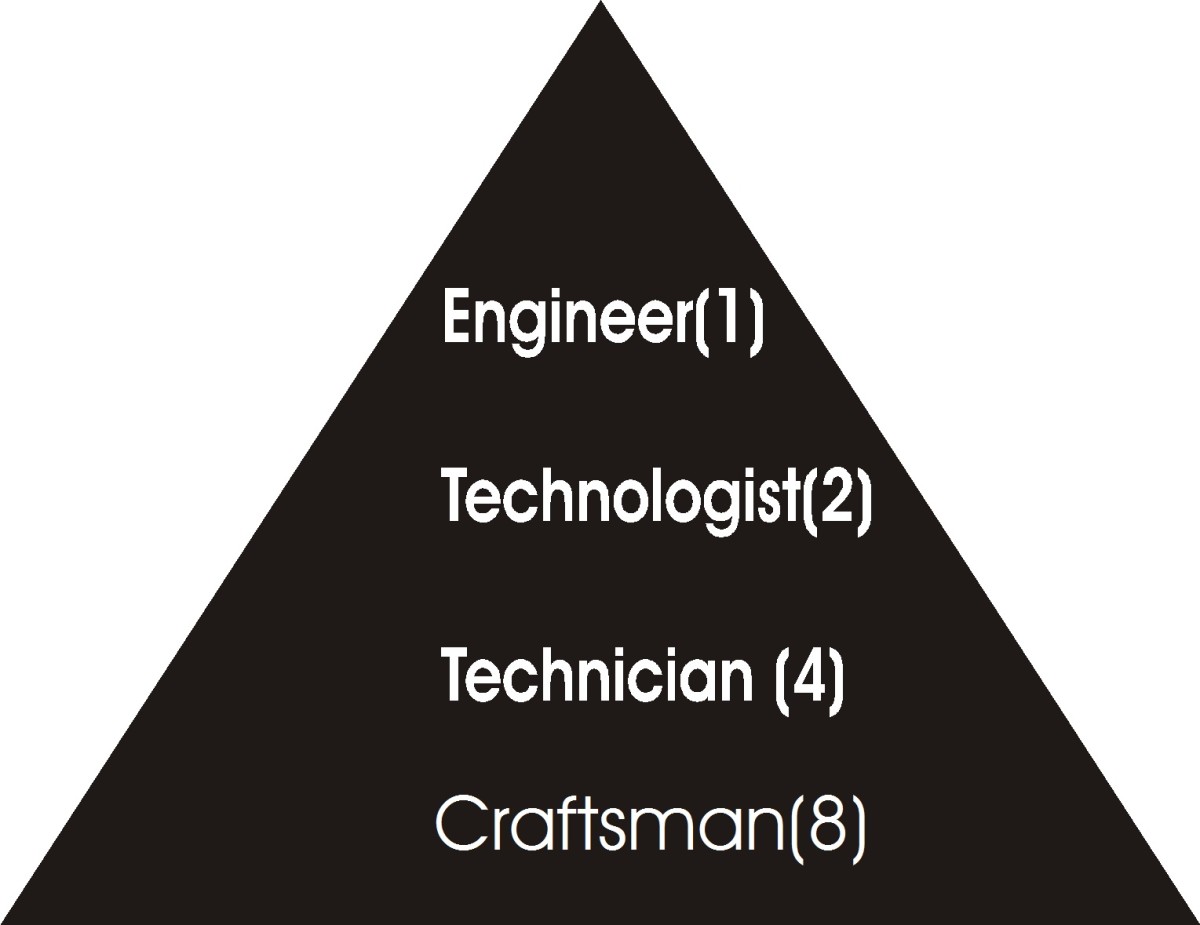

Run to failure maintenance plans, while common, are not the best strategy for keeping bioprocesses up and running and saving money. Comprehensive microbial control strategies effectively help to reduce bio-processing contamination events. Annual process reviews are recommended to allow for policy changes based on preventative maintenance and changes all aspects of the bioprocess. When reviewing the sterile bioprocess equipment, focus must be placed on many aspects of the system. First, you must identify and analyze all places where the sterile boundary may be breached.

- Are all of the drains in the process working, and do they drain every portion of the process completely?

- Have all filters been tested? Are they ceramic? Sintered metal or glass? Fibrous? Membrane Cartridge? Each has different benefits and drawbacks. Finding the right solution for your process can be a challenge? Has your process procedure taken into account the latest filter products?

- Is your steam as sterile as you think it is? The water used for the steam may need to be filtered. It cannot contain contaminants such as amines that can contaminate the process before it is sterile. Generally, saturated steam is preferred. Heated to 121oC at 15 psig allows for the most efficient sterilization to occur. Supersaturated steam will not allow for sterilization as quickly of efficiently, and may even contribute to condensate buildup that is likely to encourage microbial contamination.

- Are drain and condensate lines piped appropriately? According to the FDA, inadequate slope of condensate lines is one of the most common causes of microbial contamination in bioprocesses. All transfer lines into the process must be examined as well. Have all of your valves been checked? CAN all of your valves be checked? Valves are a common source of contamination.No matter the valve’s purpose, it can be a source of be and foreign body introduction. Opening and closing valves such as gate, globe, piston and butterfly valves can leak at the stem, or may not seal completely. Plug valves and ball valves often do not seal completely and may leak contaminants, or may not open completely and therefore not be sterilized completely.Check valves and pressure control valves may leak too much or not enough and cause the parameters of the process or the sterilization to fail. Safety valves can even leak enough to cause contamination without visible damage.

- Elastomers including o-rings and gaskets can be easily damaged, worn, or even non-existent. Any of these circumstances can be an easy intrusion into the process. Rubber, butyl rubber or neoprene composition can all easily leak enough to admit contaminants.

- Even if the process is initially sterile, even small changes throughout the life of the equipment can cause large disruptions in the sterility of the process. A change in a filter type may cause incomplete air purging and inadequate steam sterilization. Dead legs and cold or hot spots may be caused by the changing of a valve or the removal of process controls. New controls are often use because they can serve many purposes from a single device. Removal of multiple older devices may cause a new location for concern.

- Any welded joint, or threaded or bolted connections can be a sourcing a of contamination to a bio process vessel, or to any additive introduced to the system. Even a small invisible flaw in a welded seam can be a source of contamination. Grinding and swabbing of suspect areas is not the most efficient method of locating microbial intrusions.

Sterile Process Piping Isn't Always Sterile

Microbial Contamination of a Sterile Production Can Be Costly

Whether you are making bacteria, yeast, or algae, contamination in your process can be costly in terms of time, and product. Effective microbial control strategies help to reduce bio-processing contamination events. Many factors come together to create an effective strategy. The factors that contribute to an to effective bioprocess quality control include:

-

The raw input materials

-

Personnel, training and operations.

-

Input gas, air and water quality

-

The process design

-

Cleaning, sterilization and assembly

All of these must be accounted for in order to assure high quality product and yield.

The raw input materials can be checked and tested to assure that the contamination is not present prior to input into the process.

Personnel training and monitoring can be focused on equipment maintenance, instrument recalibration and process re-qualification.

Input utility quality can be tested prior to adding to the process. Poor quality input utilities often lead to bio-film contamination in the form of gram negative bacteria.

The process design can be faulty in many ways. The filter porosity can be too great, or too low resulting in too large of a pressure drop. Occasionally, improperly validated hold times of buffer solutions, or in-process intermediates can lead to contamination. Process design flaws can present the most challenging aspects of a contaminated process to track down.

Many of the techniques that are still used today to find faults in the physical process are the same as have been used for 50 years. From leak detecting foaming soap to swabbing locations all over the outside of the vessel in the hope of getting lucky, and finding a leak large enough to be the sole cause of the microbial contamination. United Leak Detection has cost effective alternatives that find big leaks that are causing problems now and leaks small enough that they will cause trouble in the future.

Many kinds of organism can contaminate your process

What is the most difficult organism to keep out of your system?

Helium and trace gas detection can find even the smallest leaks quickly

Trace gas detection can help to find even the smallest leaks. A vessel can be pressured up with either helium or an inert nitrogen/hydrogen mixture and leaks can be detected in concentrations in the parts per billion in some cases. This is by far low enough to make sure not even the smallest viruses can find their way into your system. Trace gas detection will find leaks in many parts of the bioprocess. It allows the testing of all welded joints, and gaskets and o-rings, sight glasses and sampling locations. The process is scalable to any size process and can be part of a comprehensive preventative maintenance plan. We can schedule work during planned shut downs or can respond quickly in case of an emergency contamination. An even better idea is to schedule service at installation or during scheduled downtime. You will never miss an opening timeline or have an unplanned shutdown again!